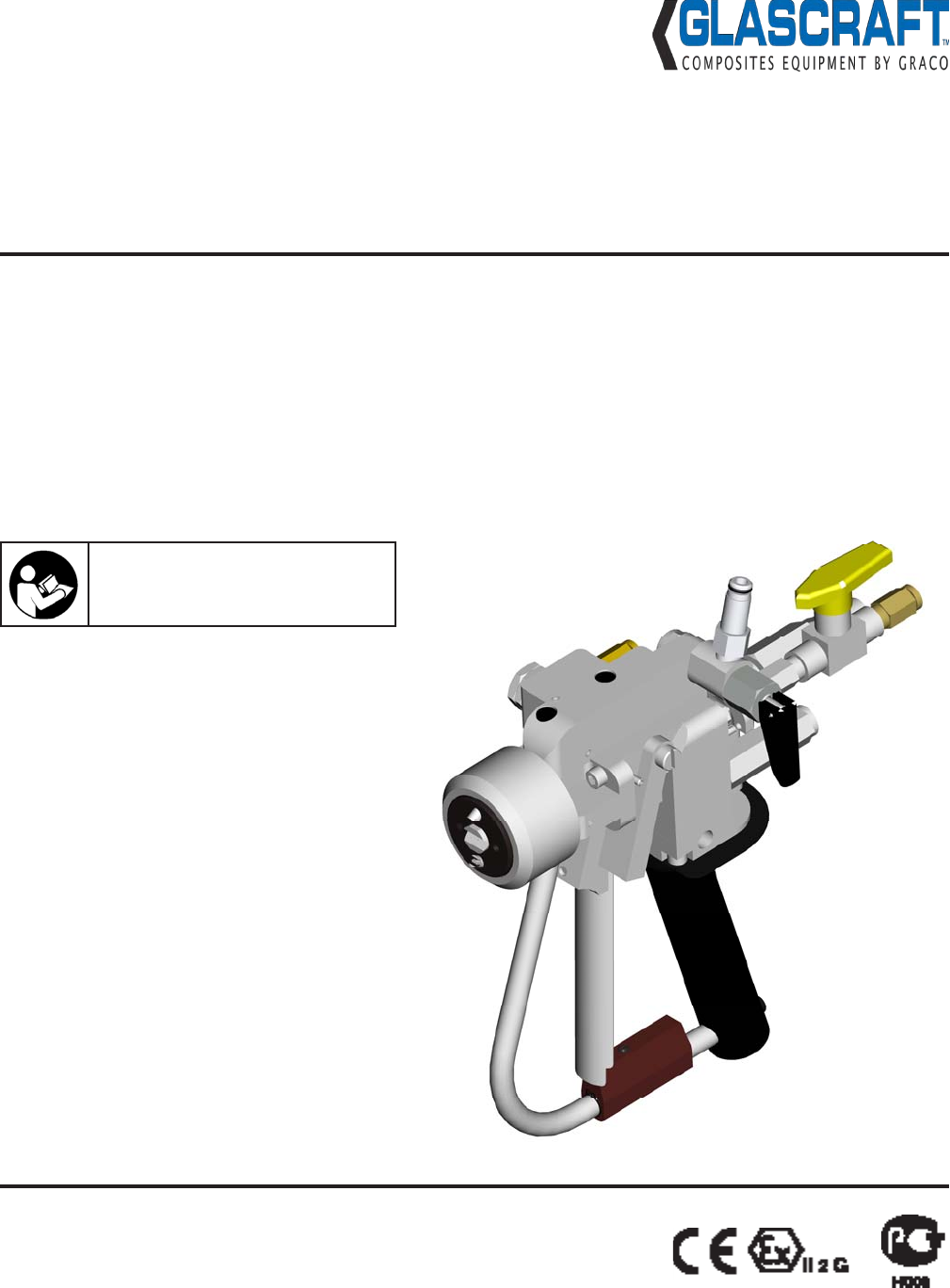

Graco Inc. Glascraft GC-1388G User Manual

Browse online or download User Manual for Paint Sprayer Graco Inc. Glascraft GC-1388G. Graco Inc. Glascraft GC-1388G User's Manual

- Page / 24

- Table of contents

- BOOKMARKS

- GC-1388G 1

- Contents 2

- Changing Materials 3

- Warnings 4

- Important Safety Information 5

- Grounding 6

- 7GC-1388F 7

- 23557-00 O-RING KIT 8

- 23558-00 MAINTENANCE KIT 8

- GC-1388 User Manual 8

- Assembly Drawings 10

- Pressure Relief Procedure 14

- Maintenance 15

- 2 20

- 21GC-1388F 21

- 22 GC-1388F 22

- Technical Data 23

- Graco Ohio Information 24

Summary of Contents

OperationIndy-X Chop GC-1388G ENGImportant Safety InstructionsRead all warnings and instructions in this manual. Save these instruct

10 GC-1388F 23575-00 Indy X Chop Dispense GunNote:Use p/n: LPA2-123S and p/n: LPA2-124Swhen using LPA2-147-XXXX and 23047-XX series spray tips

11GC-1388F 23575-00 Indy X Chop Dispense GunAssembly Drawings

12 GC-1388F 23575-00 Indy X Chop Dispense GunAssembly Drawings

13GC-1388FPartnumberDescription Qty.11021-41 PIPE PLUG 213076-06 O-RING 113867-03 O-RING 113867-05 O-RING 113867-07 O-RING 313867-09 O-RING 115845-01

14 GC-1388F To relieve uid and air pressures: 1. Push down Yellow slide valve, P/N 21402-00 to bleed off air to system.

15GC-1388FParts Replacement ProcedureBefore performing maintenance on the dispense gun, follow Pressure Relief Procedure.Due to the different o-ring m

16 GC-1388F12345Needle & Pin Removal Procedures1. Remove needle collets. (3/8in. Wrench)2. Remove set screws. (5/64in. Hex Key)3. Remove needle g

17GC-1388F21222-0020507-00(Retainer) If Packing, P/N 20507-00 and Packing Disks, P/N 20508-00 are removed from Needle and Pack-

18 GC-1388FOKOK53421FlushNeedle & Pin Reassemble Procedure1. Reassemble the needle assemblies to the gun body. Lubricate the o-rings & use te

19GC-1388FNOT OKSet Screws 5/64in. hex keyTrigger & Needle Guard Readjustment ProcedureIf you trigger the gun and notice that one needle is activa

2 GC-1388FContentsWarnings ... 3Important Safety Information ... 5Groundi

20 GC-1388F1Remove the triggerfrom gun. Slide itdown and to the side. 2Slide the gun pins, p/n 23514-00 forward to allow acces

21GC-1388FPartNumberOrice Min.Width (in.)Max.Width (in.)Min.Output (lbs.)MaxOutput (lbs.)23005- C40.040 7 16.5 5.4 10.02 C50.050

22 GC-1388F Impingement Dispense Tip Reference Chart Airless Dispense Tip Reference ChartPartNumberOrice 23047-J1 .012

23GC-1388FTechnical DataCategory DataMaximum Fluid Working Pressure 2000 psi (13.8 MPa, 138 bar)Maximum Air Inlet Pressure 100 psi (.69 MPa, 6.9 bar)T

Graco Ohio Standard WarrantyGraco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free fr

3GC-1388FWarnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point

4 GC-1388F WARNINGSKIN INJECTION HAZARD High-pressure uid from gun, hose leaks, or ruptured components will pierce skin. This may look like just a

5GC-1388FImportant Safety InformationMethyl Ethyl Ketone Peroxide (MEKP) MEKP is among the more hazardous materials found in commercial c

6 GC-1388F This equipment needs to be grounded. Ground the dispense gun through connection to a GlasCraft approved grounded uid supp

7GC-1388FRotate trigger lock to stop the triggerfrom being activated. Hose Attachment 1. Engage the trigger lock. 2. Attach the (blac

8 GC-1388F Indy-X Chop Dispense Gun 23575-00 Repair Parts Kits:Part NumberDescription23557-00 O-RING KIT23558-00 MAINTENANCE KITStandard Equip

9GC-1388F1231) Catalyst seat assembly p/n: 23544-002) Material seat assembly p/n: E-1353) Material needle valve assembly p/n: 23545-00 23575-00 In

(18 pages)

(18 pages)

(8 pages)

(8 pages)

Comments to this Manuals